VDI & BMT Tooling

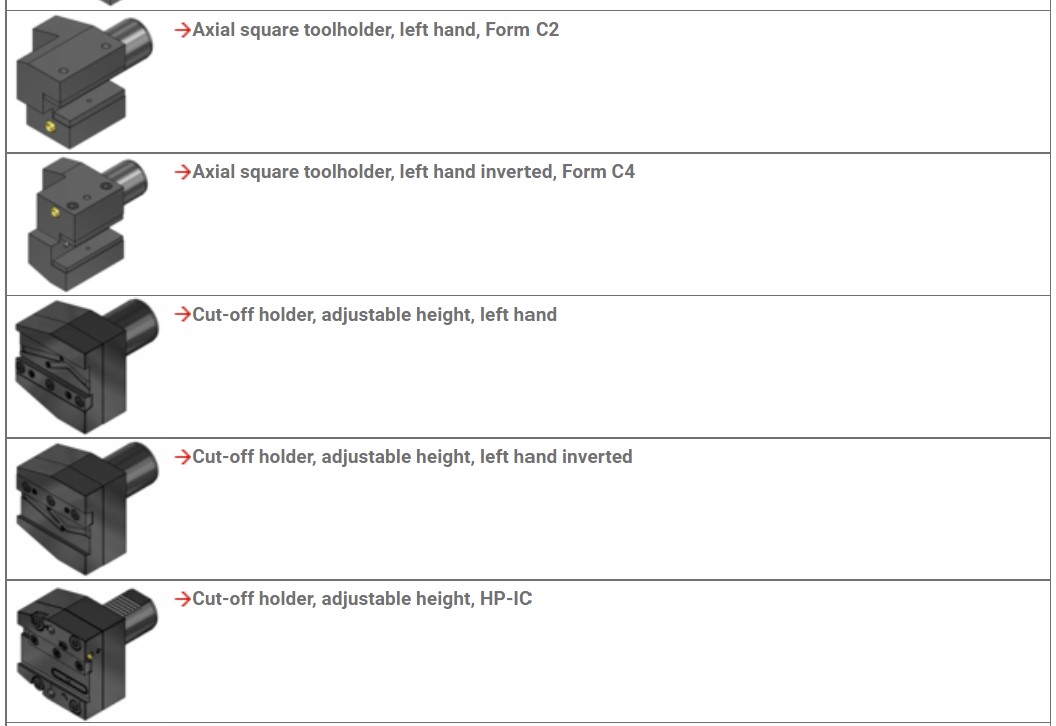

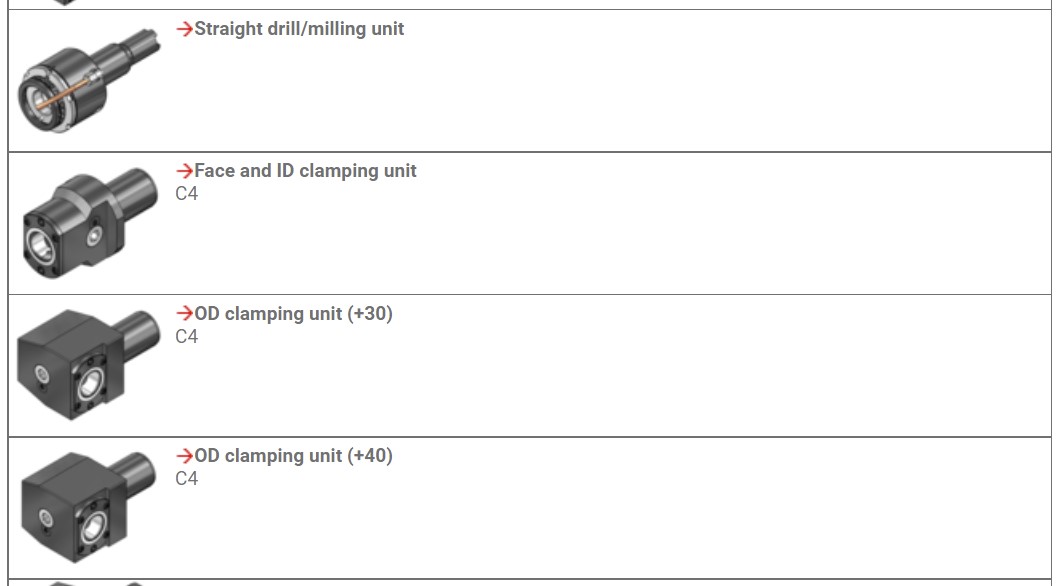

Regardless of the machine tool builder, there are basically two popular methods of mounting toolholders to your mill-turn machine…BMT or VDI. Some builders even offer machines with both turret configurations as an option – however, they usually standardize on one or the other based on a particular market or sales region.

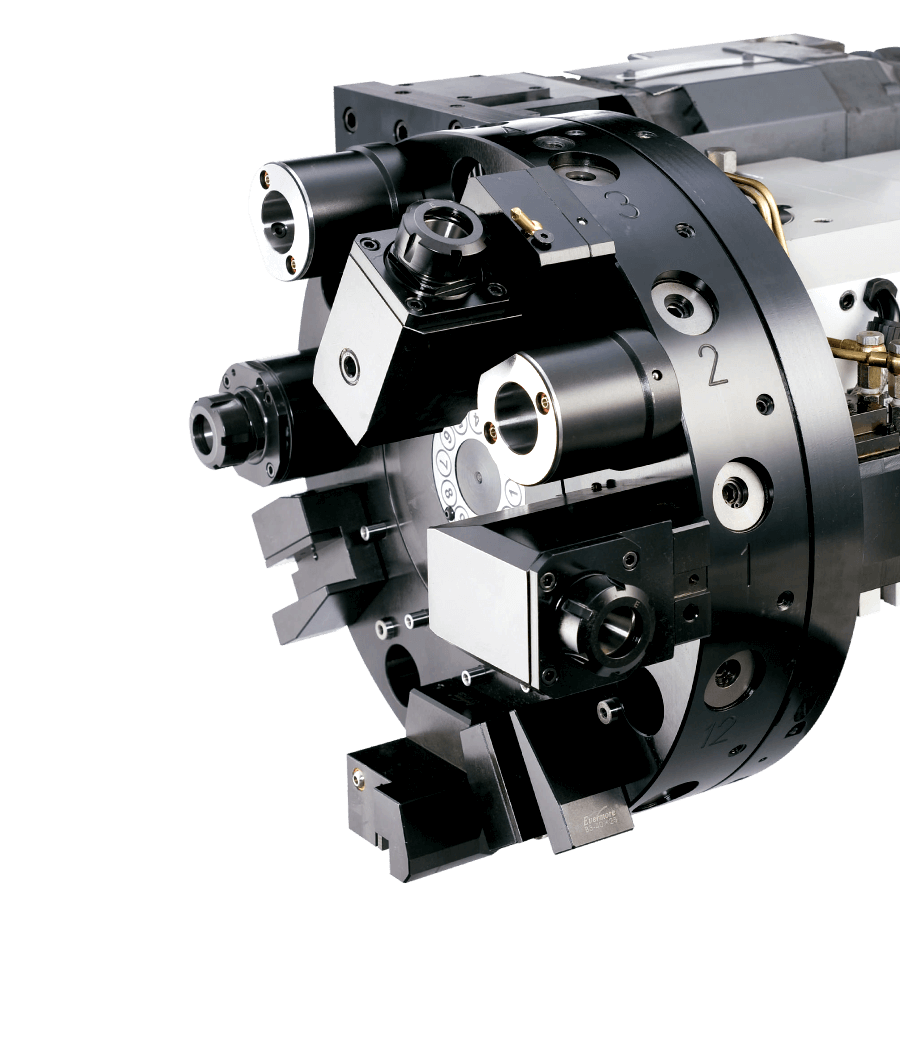

The BMT, or “Base Mounted Turret”, is often thought to be a more rigid setup overall. The BMT holder will mount solidly to the face of the turret with 4 socket head cap screws, and is located and further secured with locating keys present on the turret face. These keys eliminate the need for indicating the toolholder to straighten it…which is most often necessary with VDI toolholders. Also, the simple design of the BMT holder’s mounting configuration makes it a good candidate for DIY (do it yourself) holders for special circumstances – something that would be very difficult with VDI.

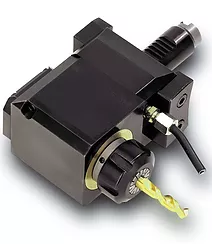

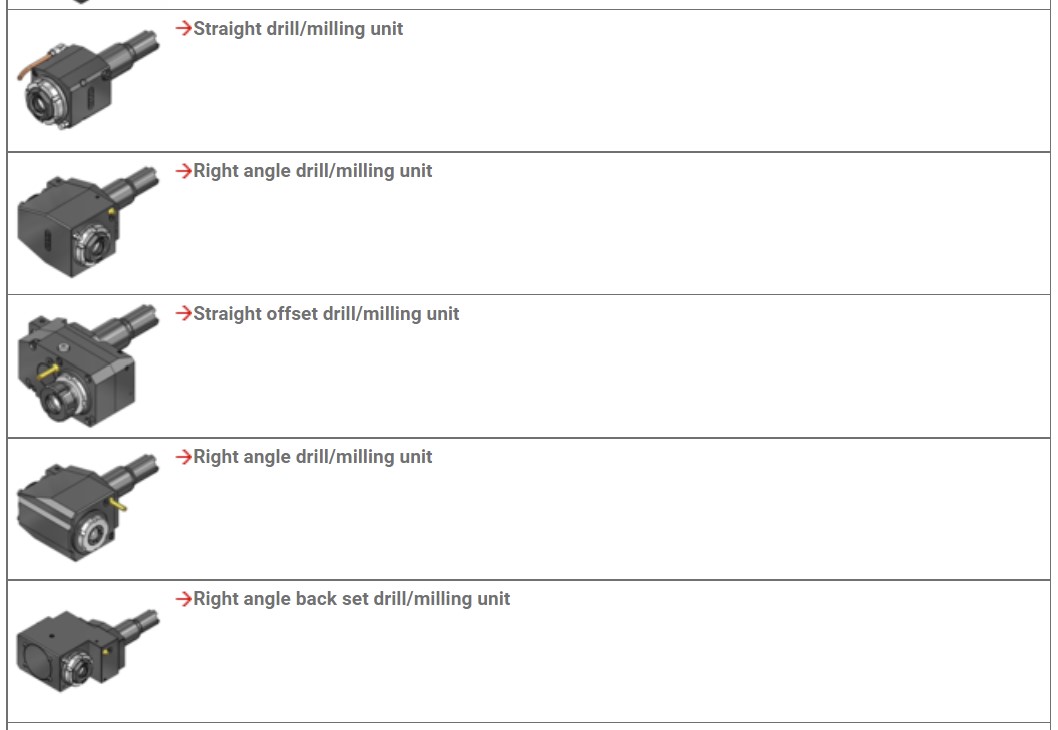

VDI holders (or “Verein Deutscher Ingenieure”, which roughly translates to Society of German Engineers) have a serrated shaft that is inserted into an opening on the face of the turret. The tool is held in place by a mating part with teeth that is housed inside the turret…when an Allen wrench is used to tighten the locking screw, located on the face of the turret, the mechanism applies clamping pressure that holds the tool securely in place. The holder is kept from twisting by a pin that is located on the mounting surface of the turret.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.